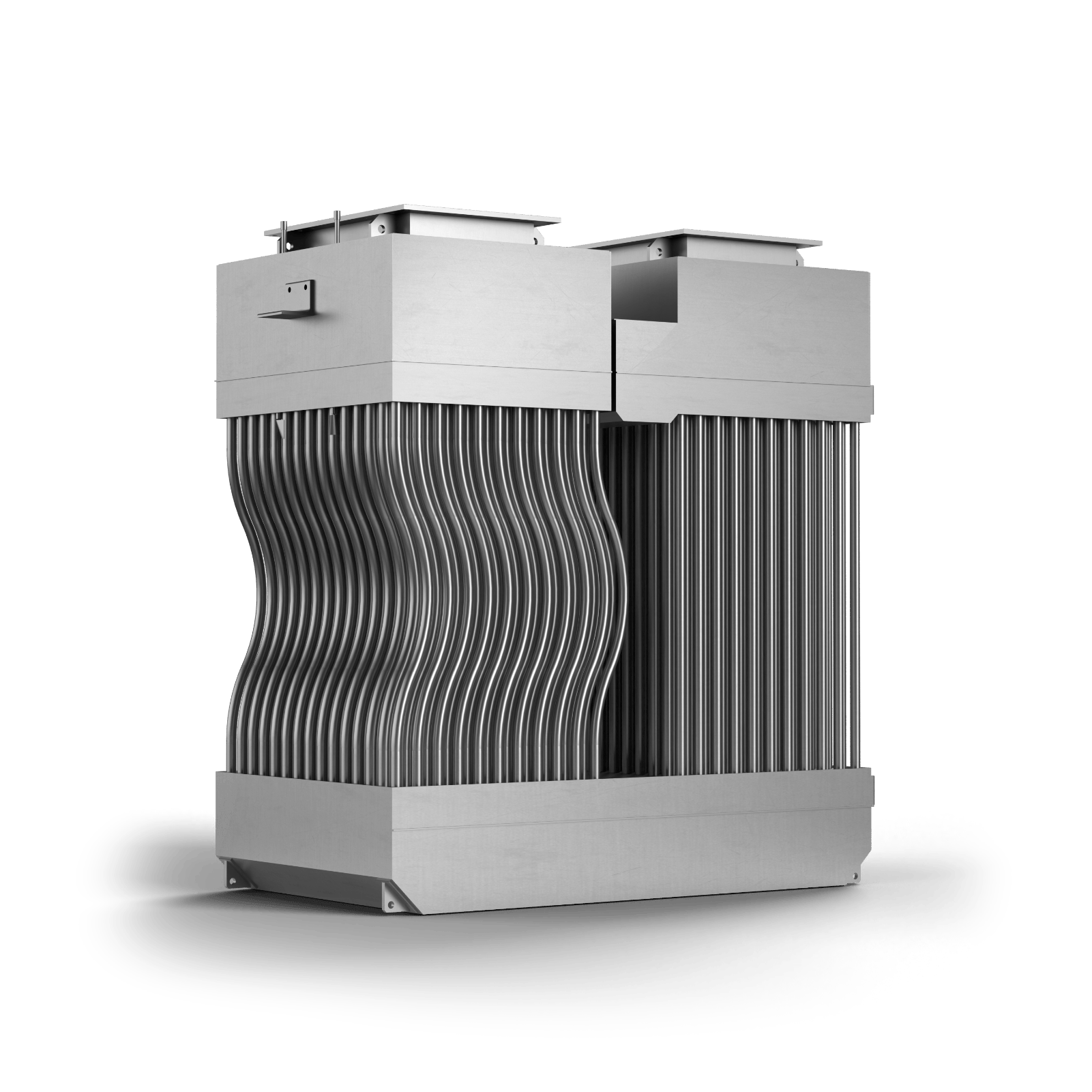

Efficient recuperation for the aluminium industry

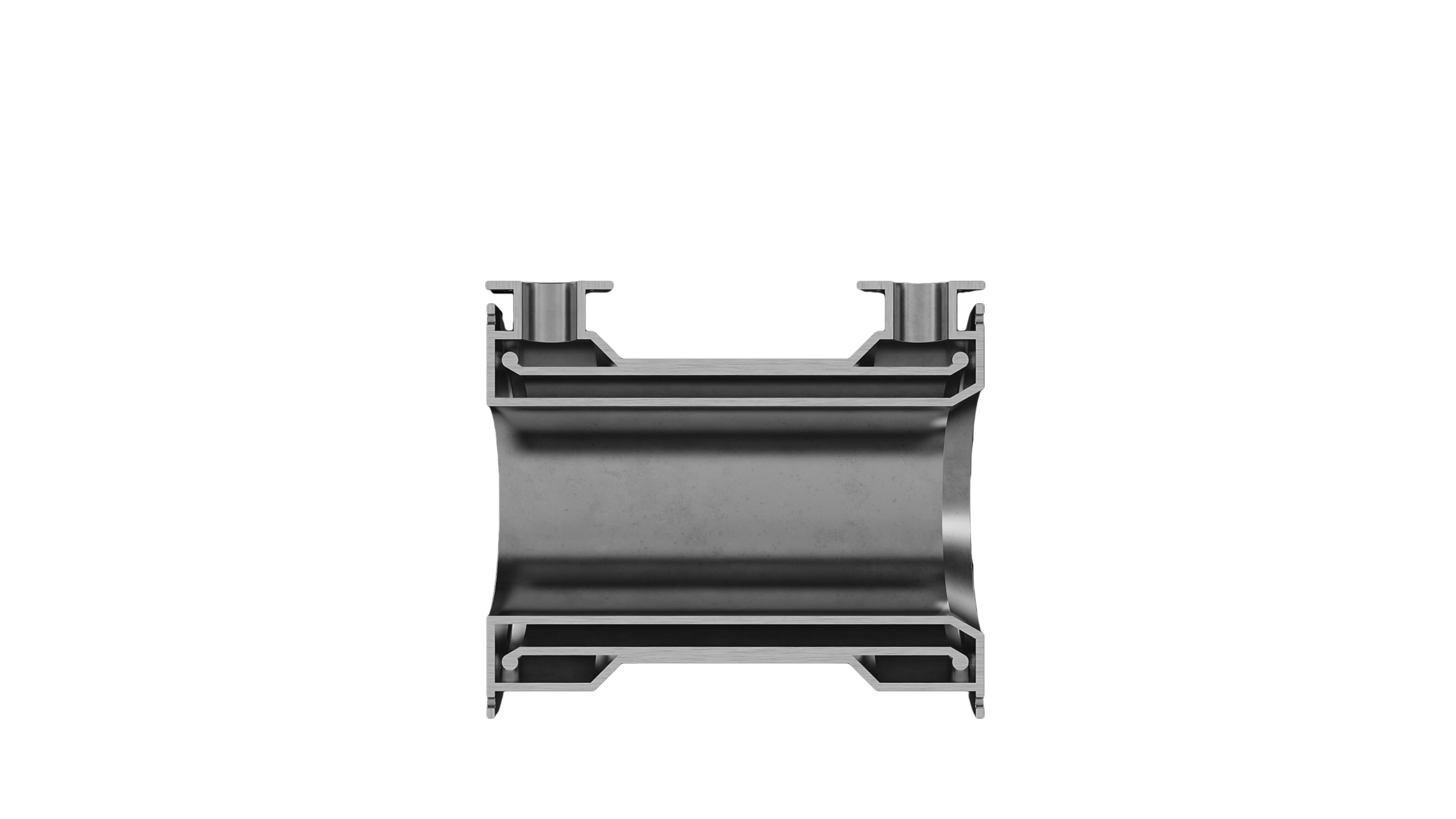

The RadiaMant dissipates heat in a single double-shell tube making it paricularly resistant and durable.

Peiler Montanwärme GmbH

Ferdinand-Zeppelin-Straße 13

47445 Moers

Sie möchten Sich für folgende Stelle bewerben: