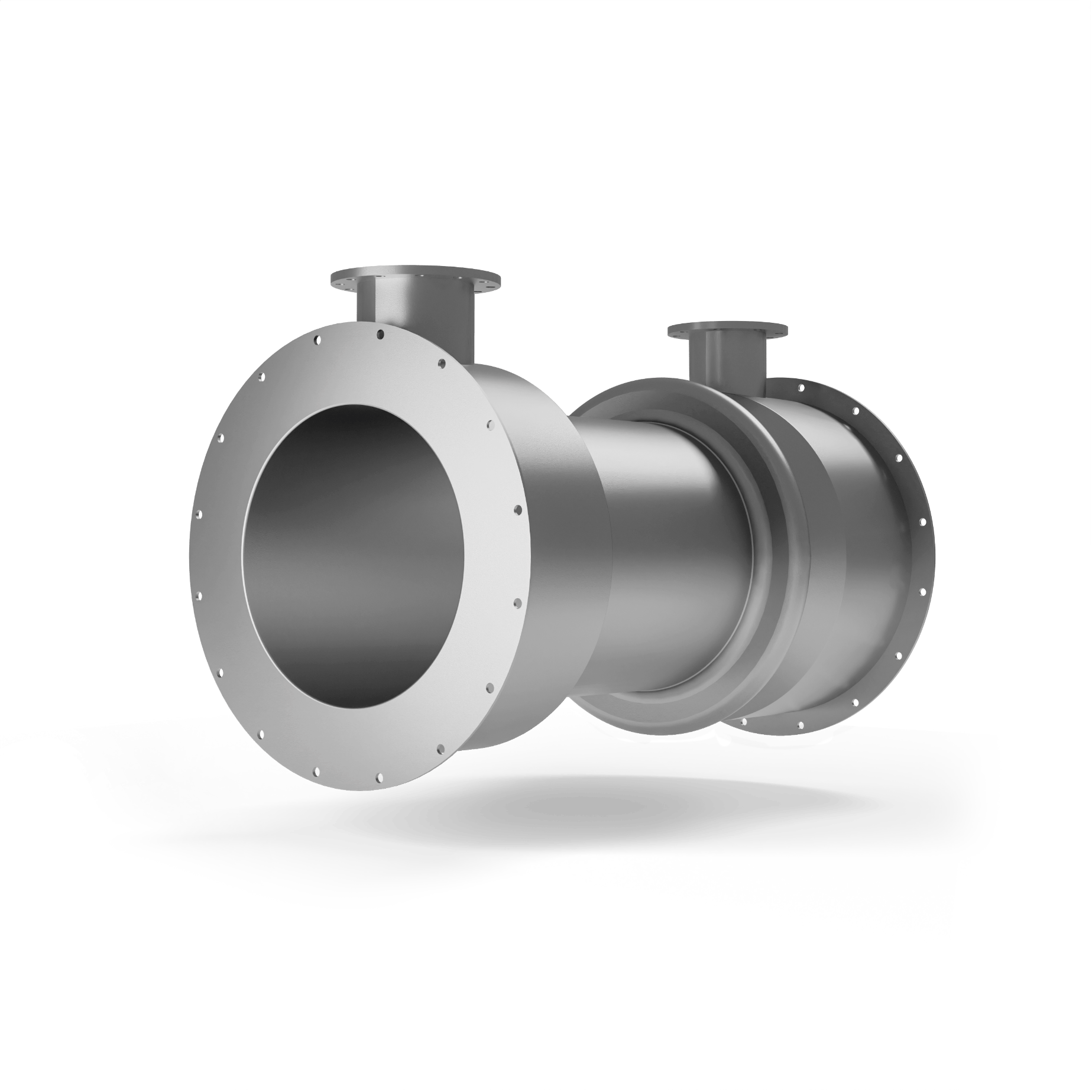

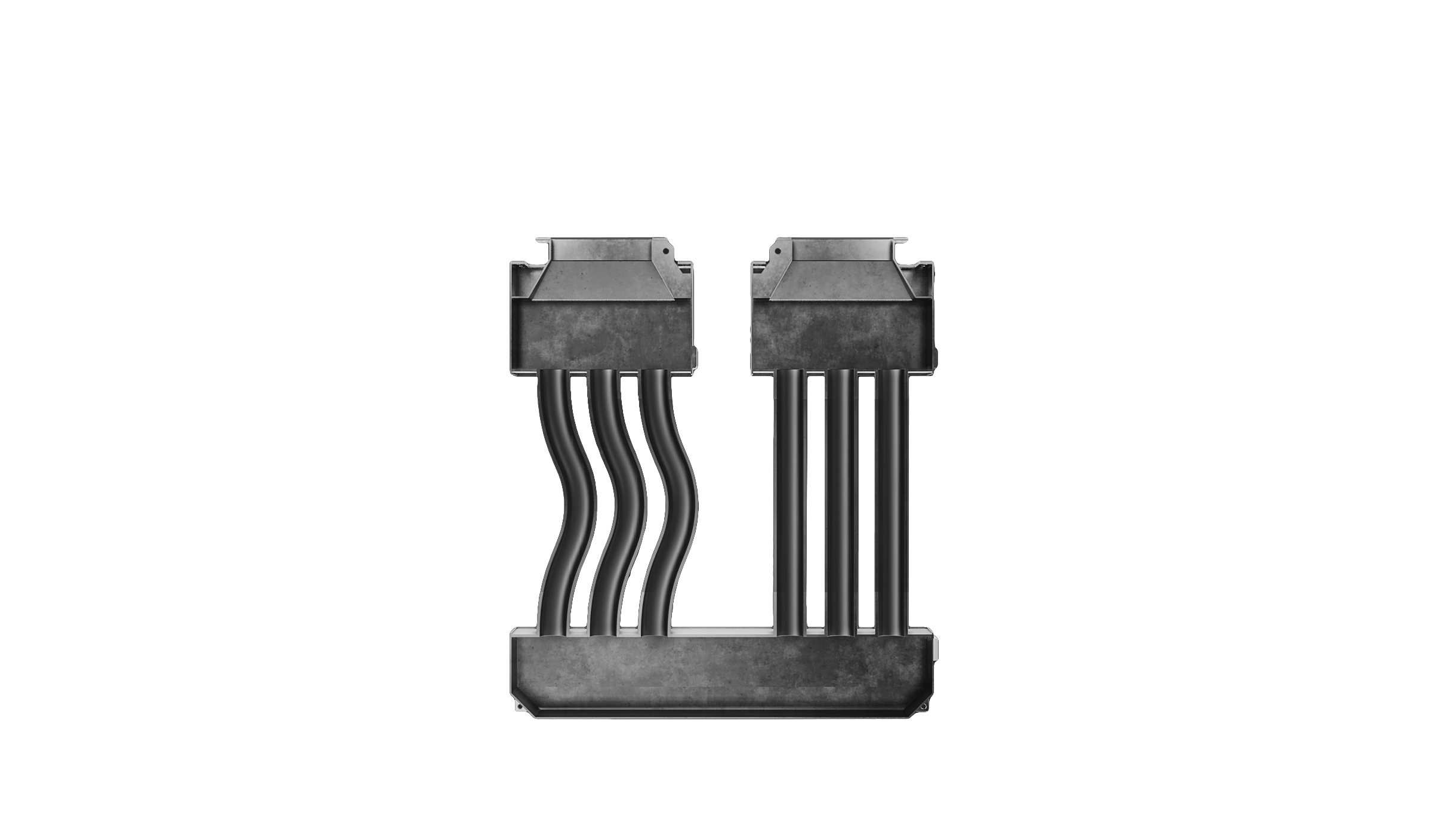

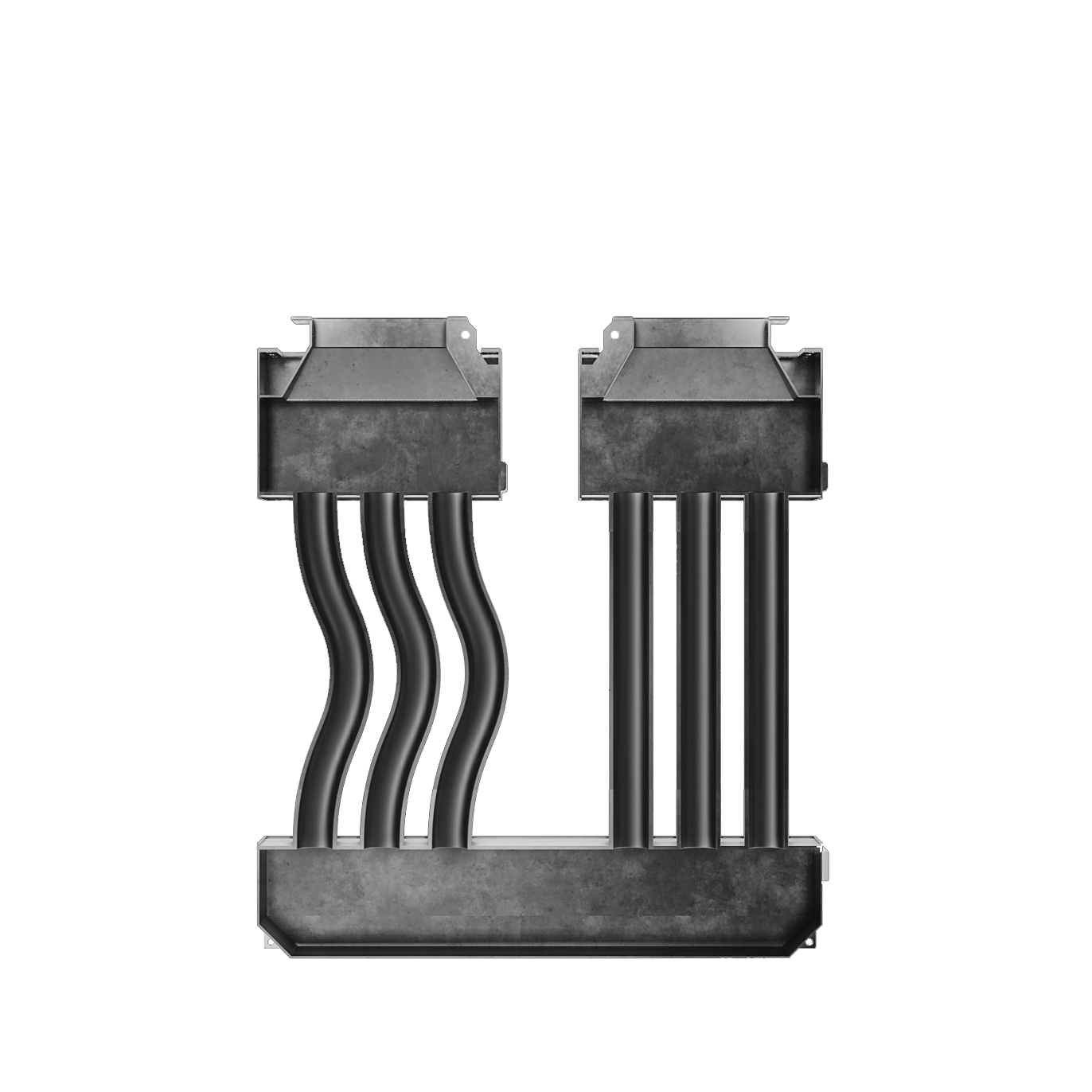

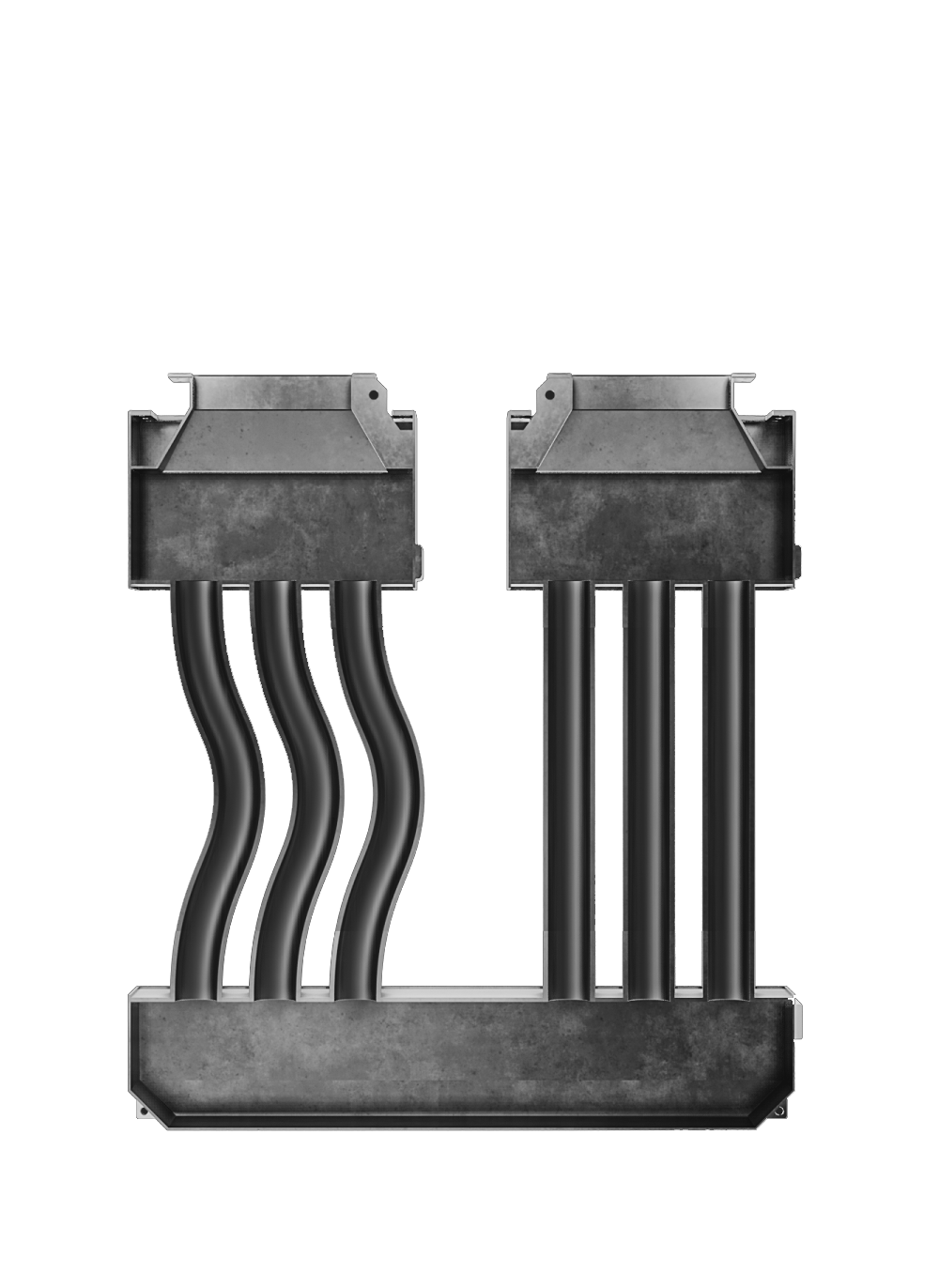

Double-walled, resistant and durable

The convection recuperator works particularly efficiently. It achieves a high level of efficiency even at low flue gas temperatures.

Peiler Montanwärme GmbH

Ferdinand-Zeppelin-Straße 13

47445 Moers

Sie möchten Sich für folgende Stelle bewerben: